-40%

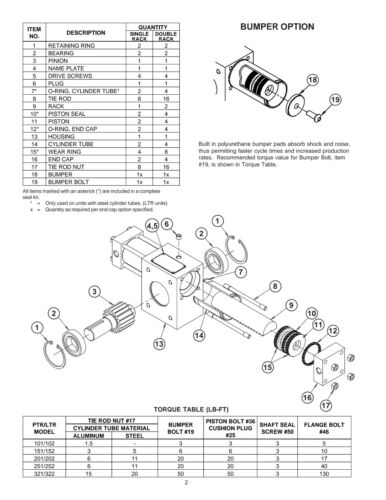

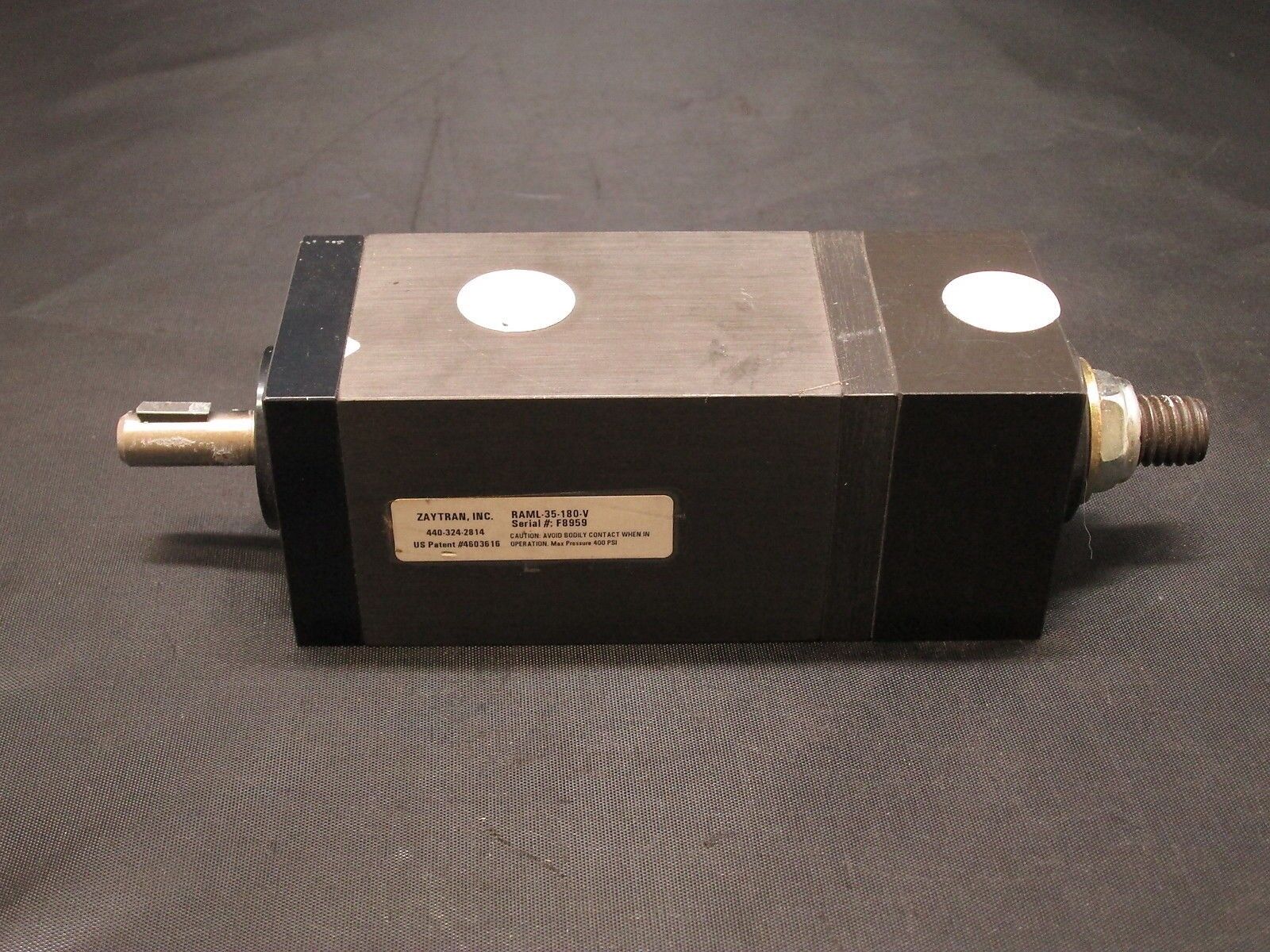

Two (2) Parker Pneumatic Rack and Pinion Rotary Actuators

$ 264

- Description

- Size Guide

Description

QUANTITY : 2Parker Pneumatic Rack and Pinion Rotary Actuator

P/N: PTR252-180L-GA21M-C

These are two working rotary cylinders taken off a machine that was being parted out for surplus.

The machine was stored inside but after so long there is some very light exterior only rust on the actuators.

The machine was just disassembled last week and since then I have plugged up the bore orfices as not to get any damaging debris in them.

The following is off of Parker's website catalogue. If you have any further questions please feel free to ask and I'll do my best to get you the answers.

Thank You for looking.

PERFORMANCE CHARACTERISTICS

PRODUCT TYPE

Rack and Pinion

STANDARD ROTATION (DEGREES)

90 | 180 | 270 | 360 | 450

FULL ROTATION RANGE (DEGREES)

20° to 450°

TORQUE RATING (IN-LBS)

39 to 2281 @ 100 psi

TORQUE RATING (NM)

-

MAXIMUM PRESSURE (PSI)

250

MAXIMUM PRESSURE (BAR)

17.2

TEMPERATURE RANGE (F)

0° to +180° (for Nitrile Seals) | 0° to +250° F (for Fluorocarbon Seals)

TEMPERATURE RANGE (C)

-18° to +82° (for Nitrile Seals) | -18° to +121 (for Fluorocarbon Seals)

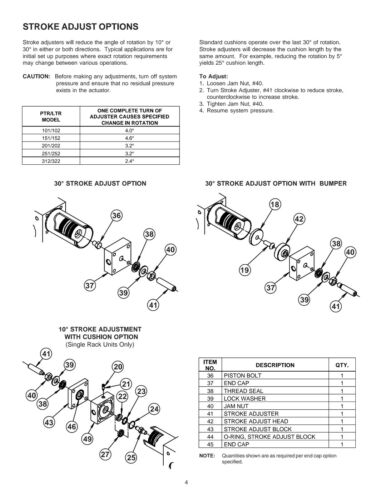

STROKE ADJUSTMENT

None | 0-30° CW Rotation | 0-30° CCW Rotation | 0-30° Both Rotations | Shock/Stroke Adj. CW Rotation | Shock/Stroke Adj. CCW Rotation | Shock/Stroke Adj. Both Rotations

CUSHIONING TYPE

None | CW Rotation only | CCW Rotation only | Both Rotations | Four | Bumper CW Rotation only | Bumper CCW Rotation only | Bumper Both Rotations

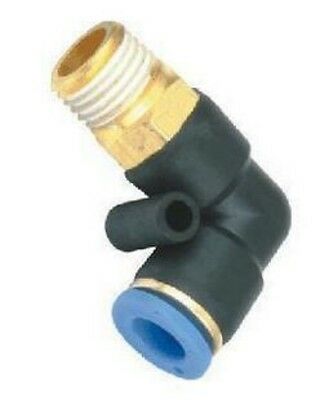

PORT TYPE

SAE straight thread | NPTF | BSPP

PORT SIZE

7/16-20" | 9/16-18" | 3/4-16"| 1/8" | 1/4" | 3/8"

POSITION SENSING

Yes

SENSOR TYPE

Proximity | Hall Effect | Reed

BODY MATERIAL

Aluminum

SHAFT MATERIAL

High Strength Alloy Steel

SEAL MATERIAL

Nitrile | Flourocarbon

WEIGHT (LB)

2 to 76

WEIGHT (KG)

0.9 to 34.4

MAXIMUM OPERATING FREQUENCY

N/A

PRODUCT OVERVIEW

Print Product OverviewThe PTR series rotary actuator is ideal for most pneumatic applications. The PTR Series actuator combines an alloy steel gear set with a high strength, anodized aluminum housing and Parker 3L or 2A Series cylinder components into an actuator suitable for years of trouble free service. The actuator maximizes volumetric efficiency by using self-energizing PolyPak seals. Mechanical efficiency is maximized by using antifriction bearings and Wear-pak® piston technology.

• Output torques @ 100 psi (6.9 bar): 39 lb-in to 2,281 lb-in

• Nominal pressure: 100 psig (6.9 bar)

• Operating temperature range:

o Nitrile seals 0° to 180° F (-18° to 82°C)

o Fluorocarbon seals 0° to 250°F (-18° to 121°C)

• Standard rotations: 90°, 180°, 270°, 360°, 450°

• Rotational tolerance: -0°, +2°

• Maximum breakaway pressure: 5 psig (0.4 bar)

• Mounting orientation: unrestricted

• Standard timing: keyway in 12:00 position at midstroke

• Recommended filtration: 40 micron filtered, dry air

• Pneumatic cushions to minimize noise, vibration shock and assist deceleration control

• End-of-rotation stroke adjusters for load position control and accurate rotation adjustment

• Polyurethane bumpers to absorb shock & noise, thus permitting faster cycle times and increased production

• Built-in meter out flow control valves provide precise adjustment of actuator speed

• Reed, Hall Effect or proximity switches for position sensing

• Self contained air/oil option for pneumatic operation with no slipping, jerking or bouncing

• Three position option can be used with many special machine and material handling applications

Rack and pinion design provides excellent efficiency characteristics

Large Hollow Gears Offer More Shaft Options

PTR series are designed for Low Wear on dynamic seals and longer life

Excellent in High Speed Production Application